Leaf Expression Systems was established in 2017 as a spin-out company from the John Innes Centre, and is situated within the scientific hub that is the Norwich Research Park, home to world-class research into plant science. Leaf Expression Systems runs independently in its own purpose built facility, where a dedicated team of scientists work on bringing technology developed at the John Innes Centre into a commercial reality.

We hear today from one of the scientists involved in the research carried out at Leaf Expression Systems, Dr Claire A Fowler. Claire will give us a brief overview of the exciting science that goes on at Leaf Expression Systems, and her thoughts on what the future holds for this growing company.

Plants have a long history of use within medicine, with many important drugs being based on chemicals identified in plants; aspirin, morphine and quinine being the most well known. Plants are complex organisms that can make lots of different types of molecules; chemicals like aspirin, but also complex biological molecules known as proteins. The function of proteins varies widely and their use in medicine is already widespread. Proteins for medicinal use are traditionally made industrially in bacteria such as E.coli or in more complex mammalian cells (cells similar to our own), but what about making medicinal proteins in plants? Can we harness the power of plants for the benefit of wider society, and use them in the production of proteins to act as therapeutic drugs, diagnostics and vaccines?

At Leaf Expression Systems, we aim to do just that. Through a process called molecular ‘pharming’, we can turn plants into miniature bioreactors capable of producing (‘expressing’) high value biological molecules, such as proteins. We are focused on using this technology to improve lives by accelerating research and lowering costs in the development and manufacture of therapeutic drugs, vaccines and diagnostics for human and animal health (‘biologics’).

At our UK-based facility we act as a contract development and manufacturing business. Using our proprietary, protein expression technology, Hypertrans®, we specialise in the production of biological molecules for research and medical applications.

Our miniature bioreactor, the plant Nicotiana benthamiana

How can plants be used to produce these proteins?

We think of our plants as ‘mini-bioreactors’; imagine the huge stainless-steel tanks used in breweries where you add together water, barley, hops and then yeast (a living organism) which ferments them to make beer. Plants act in the same way when they have the ingredients they need to grow; water, nutrients, light, etc. If we want a plant to make a specific protein for us, we just need to add another ingredient, DNA. DNA is a set of biological ‘instructions’ required to make the protein. The DNA instructions are unique to the specific ‘target’ protein we want the plant to produce. The target DNA is then incorporated into our Hypertrans® system: this is simply a circular piece of DNA known as a plasmid that contains a variety of elements, as well as the instructions for the target protein which enables efficient protein production within the plants’ cells.

Small scale hand infiltration of a single N. benthamiana plant for feasibility studies

For the plant to produce the target protein, we take the circular plasmid DNA containing the biological instructions and put it into the plants’ cells. We use a process called ‘agroinfiltration’ to transfer the Hypertrans® plasmid into the plants’ cells situated in its leaves. The process uses a bacterium called an ‘agrobacterium’ as the transport vehicle. The plants are grown for four weeks and then are submerged into a liquid containing millions of individual agrobacterium, each possessing the plasmid. The plants inside the liquid are placed under vacuum (very low pressure) and when the vacuum is released the liquid containing the agrobacteria is taken up by the plant leaves into the spaces between the individual plant cells. The agrobacterium then uses specialised cellular machinery to transfer the plasmid it is carrying to the inside of the plant cells within the leaf. Once the bacteria have ‘infiltrated’ the plants’ leaves, the newly introduced DNA of the target protein is recognised and the plant cells start following the instructions to make the target protein.

Our growth rooms containing plants ready to be infiltrated

The versatility and ease of our Hypertrans® system allows us to work with a wide variety of target proteins, be that an enzyme, a monoclonal antibody, vaccine, or even complex natural products (chemicals like aspirin) – we just need the DNA sequence as the set of instructions. The plants continue to act at bioreactors, accumulating the target protein in their cells for about one week before we harvest the leaves. Using the leaves we can then start to work on purifying the target protein away from the rest of the native plant proteins by using traditional purification techniques.

How can using plants benefit research and development?

Molecular pharming is a much cheaper process to run than traditional protein production platforms due to the simplification of the infrastructure – the plants just need space, light and water. Protein production in plants scales in a linear fashion, as each plant acts as an independent bioreactor; if we want to produce more protein we simply grow more plants.

Our process is transient, meaning the genetic instructions we incorporate into the plants through our agroinfiltration process do not get passed onto another generation, as the plant is harvested before it can flower and produce seeds. Transient protein production is simple and quick, typically taking six weeks from sowing the seeds to harvesting the infiltrated plants, making the protein production process around 25% quicker than traditional methods which rely on mammalian cells.

The rapidity of the system is clear - customers can provide a plasmid containing the DNA of their target protein and we can do ‘plasmid to purification’ within about seven-10 days. Our system allows customers to quickly evaluate the feasibility of their projects and gives greater opportunity to test multiple avenues of research at the same time; the transient nature of our expression system allows us to work on multiple targets at the same time, or switch to a new target protein extremely quickly. Another benefit of protein production in plants is that we can often produce targets which have failed to be expressed in traditional expression systems; and because plants cells can act in a similar way to human cells, they are able to carry out specialised modifications on proteins which cannot occur in simpler expression hosts, such as bacteria.

R&D with plants uses lots of the same techniques used in traditional biologics production

How can using plants to produce proteins benefit lives?

From our experience and understanding of the biologics sector, plants are an under used resource; the speed of transient expression technology indicates that plants have the potential to be employed on the front line for rapid response biologics production – for example, in producing vaccines or diagnostic agents quickly as need arises, such as during the current COVID-19 pandemic.

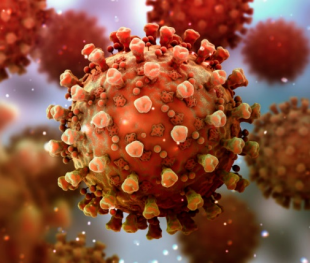

One of the attractions of our plant expression system is its ability to make very complex protein structures, for instance virus-like particles (VLPs). VLPs are made up of many copies of certain proteins that join to make a larger structure. VLPs physically resemble a target virus but are non-infectious because they contain no viral genetic material. This leads to reduced safety and regulatory concerns, and in our system potential VLP vaccines can be prepared in around 12 weeks compared with nine months for traditional technologies. This time saving is a vital aspect of effective disease response. The COVID-19 antigens we have been developing as diagnostic (testing) reagents are an excellent example which demonstrates the capability our technology to produce a rapid turnaround of targets.

Plants are able to produce virus-like-particles, often used in vaccines.

Our commercialisation framework can support several layers of the biopharmaceutical industry: direct sales to interested parties such as academic labs; materials on request through bespoke projects with clients; and research and innovation by our own internal specialists or through funded collaboration consortia. At our current facility we often work on lab-scale projects focused on small numbers of plants, as well as larger scale batch production for projects requiring material for supply. Our facility allows us to easily produce materials in ‘pilot scale’ production quantities in order to carry out feasibility studies, process development and technology transfer. Our goal over the next couple of years is to expand this to reach higher levels of industrial supply – putting us in a position where we could feasibly respond to situations of new disease outbreaks and enable rapid production of large quantities of biologics for use in animal and human health.

More space to grow more plants would increase our ability to have an impact on healthcare

What challenges do we face?

The current challenges for us as a company are to take the experiences we have gained over the last couple of years, where we have shown very positive evidence of the feasibility of our technology through the production of various products and research outputs, and use that to fuel our expansion. We want to be able to use our technology platform in a way that will bring benefit to the wider community and educate industry to embrace the power of plants. By understanding these benefits, we can then work together and focus on getting their products successfully into patients where it can make a difference.

We are actively looking at options that will enable Leaf to increase capacity and also provide Good Manufacturing Practice (GMP) compliant products for use in clinical trials and commercial supply. This would allow us to supply biologics in the quantities needed to bring benefit to customers and patients alike.

Leaf Expression Systems, our facility in Norwich

Leave a comment